Compax Inc. 1210 N. Blue Gum St. Anaheim, Ca 92806 |

Tel: (714)630-3670 Fax: (714) 632-1344 Email: earl@compaxinc.com |

Precision powder metallurgy company providing quality Powder Metal components for over 40 years.

Website for Compaxinc.com and Powdermetal.com

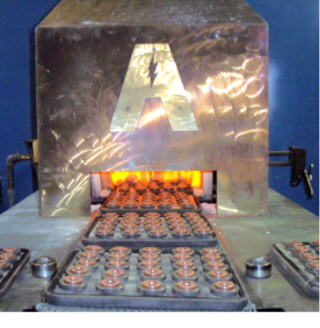

SINTERING

|

Sintering is the process of using heat to turn powdered substances into solids without actually melting the material. Sintering allows production of parts without melting and liquid casting processes, i.e., dealing with only powder or fine sand. During sintering, the pressed parts move through a controlled-atmosphere furnace. The pressed powder particles fuse together, forming metallurgical bonds. Compax, Inc. has high temperature sintering capabilities up to 3000 degrees Fahrenheit. Our "High Temperature Sintering" capability allows us to achieve the most strength from the chosen material. |

As applied to ferrous powder metallurgy, the sintering process can be defined as

"a method of controlled atmosphere diffusion bonding particles to produce an engineering material. "

Sintering is an important process for compressed powdered metal shapes,

called the green compacts. After compaction, the density and strength

of the material are low. Sintering, then, increases both properties of

the material.

Secondary Operations

In-house quality assurance and metallurgical inspection